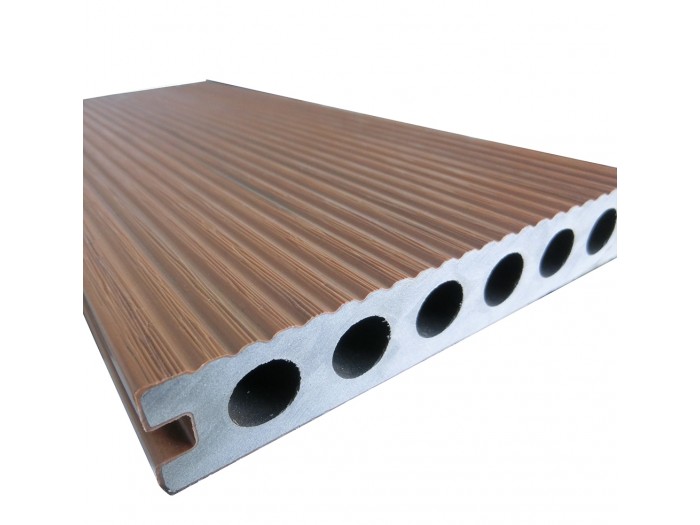

Detail Product

| Thickness: |

23mm

|

Width: |

138mm

|

| Technics: |

Wood-Plastic Composite Co-extrusion decking |

Type: |

Outlayer and Core |

| Length: |

2.2m,2.9m or Customized |

Material: |

Core 60% woodfiber, 30%HDPE, 10% additives, Layer 0.5±0.1mm polymer

|

| Color: |

Charcoal, Dark Brown, Light Brown, Redwood, Teak Gray or Customized |

Appearance: |

Wood Grain,Groove |

| Life Time: |

20 years |

Shipping port: |

Shanghai |

The composite decking has a very wide application by garden, lawn,balcony, corridor, garage, pool&SPA Surroundings, boardwalk, seaside, villa, hallway, plaza, park landscape,terrase, garden, marinas, courtyard, airport, balcony.

Elegant nature wood grain texture & touch / Eco and Recycled / No cracking, warping,and splitting / Water-proof, Corrosion-resistant / Low maintenance and no painting / Easy to install, clean / Weather resistant, suitable from -40 to 60°C / High degree of UV and color stability.

1. High Quality with CE/ISO /SGS/FSC certificate and Competitive Price

2. Professional manufacturer & export experience

3. More items for your option. Color optional, length optional, surface optional

4. Prompt delivery: 15 days per 1*20'ft container when we received the advance.

5. Free samples offer to you

| Test Duration |

6000 hours |

| Water absorption |

2.09% |

| Max loading: |

3443N |

| Flexural Strength: |

32.0MPa |

| Flexural Modulus: |

2714MPa |

| Abrasion resistance: |

Wear index: 26.0mg/1000 revolution |

| Coefficient of Liner Thermal Expansion |

|

1. Before fixing the joist, make sure the ground is solid and flat, so that the joist can be fastened tightly on the ground. Then dig holes with percussion drill in the deck area and bury the plastic tube into the holes.

2. Take the buried expansion tube as center, put the joist stably on the center line, pierce the joist with pistol drill and nail the screw into the expansion tube 300-350mm.

3. Nail the expansion screw into the top of the vertical joint of two joists.

4. Put flat the deck along the vertical direction of joists, the ending deck can be fixed on the joist with screw to make sure the accuracy of it being the base floor for other decks.

5. Install clips on the other side of the first deck, and start installing decks in order.

6. Install 2 joists in the longitudinal joint of two decks.

7. To avoid possible deformation caused by temperature change, joists can not be tied too closely.

8. Outside the last deck, use the same installation method as that of the first deck, install edge seal and terminal sealing board.

Contact:

Mail: sales.boda@bodabm.com

Tel: +86 315 5770383

Mob: +86 13784619337 (WhatsApp/Wechat)

Add:The 4th Floor, Ruanjianyuan, High-tech Zone,

Tangshan, Hebei, China 063000